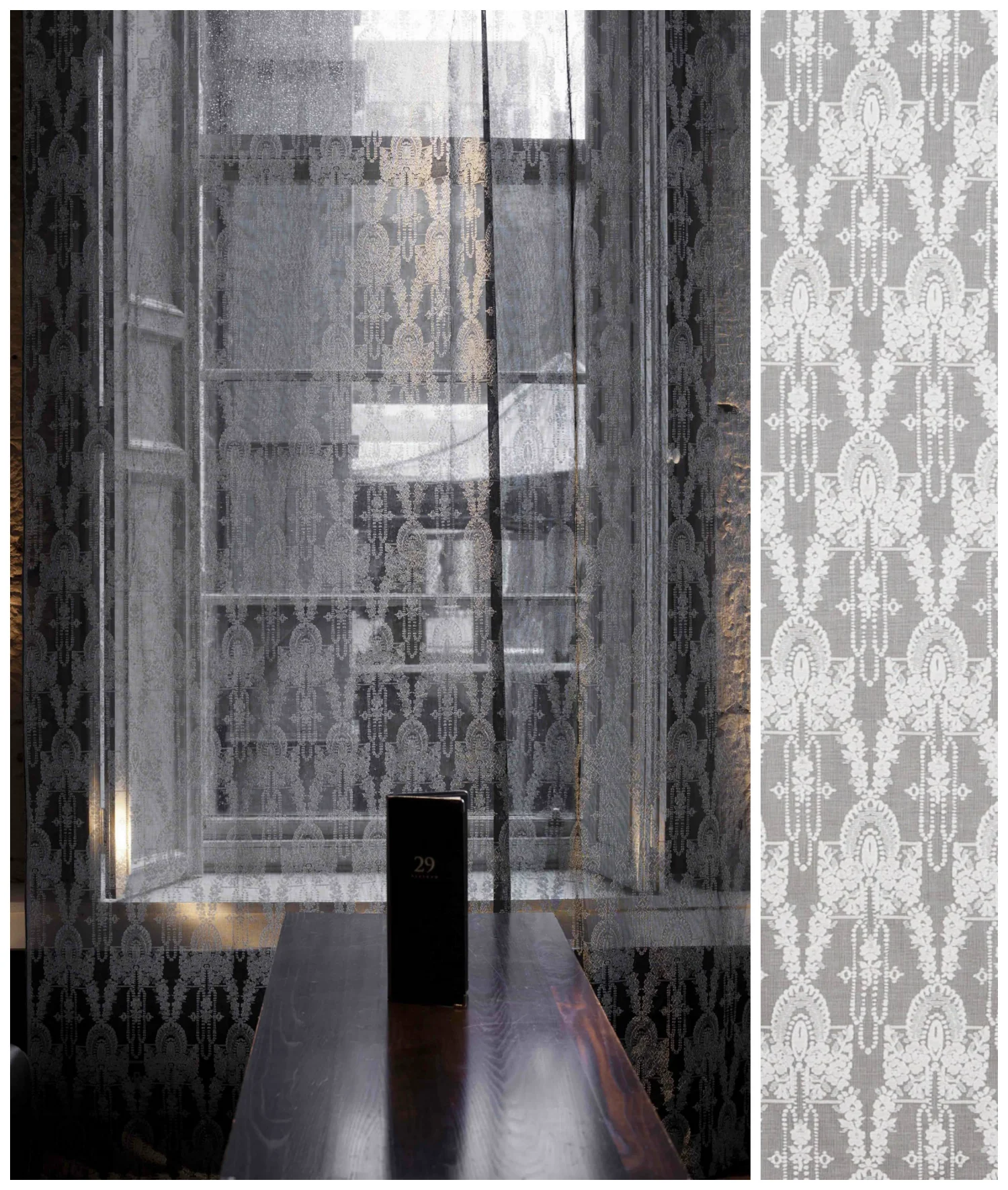

Who hasn't been seduced by the image of lace, moving softly in the breeze, with the sun streaming through leaving an intriguing pattern on the floor. Or perhaps a tuft of lace at the neckline of a beautiful woman. So romantic. Kind of feels a bit like Downton Abbey or a Ralph Lauren ad, don't you think?

Well, as it turns out, there is only one remaining mill in the world that continues to make true Nottingham lace (and its cousin, madras) - and it is, natch, the lace that you see on Downton Abbey and couture fashion from brands like Ralph Lauren, and Scottish designer Elizabeth Martin whose designs are shown above.

Who is keeping this legacy alive? The firm Morton, Young and Borland Textiles, based in Ayrshire, Scotland about 25 miles from Glasgow.

And what's so unique about MYB Textiles' lace? Two things, and both are irreplaceable. First it is the looms that their product is woven on. Nottingham refers to the place where the machine and technology for making the lace first developed, not the lace itself, and MYB Textiles' looms are over 100 years old. No other firm has them.

MYB has carefully maintained their original looms from the company's inception in the early 1900s and acquired additional ones as other companies have gone out of business. These special looms allow MYB Textiles to create wide width fabrics, with highly ornate patterns or, if need be, simple gauze-like textiles.

But don't assume that MYB Textiles is lodged firmly in the past. Rather it is the firm's unique ability to adopt modern technology while respecting it's heritage that has allowed the company to survive and thrive.

And that brings us to MYB Textiles' second unique feature. Unlike other companies that produced these textiles, MYB has installed a carefully orchestrated apprenticeship program to allow skills to be passed down from generation to generation. Plus, a look at the company's Tumblr account also reveals that they regularly take interns from Britain's designs schools, opening themselves up to fresh new ideas from young designers.

An example of MYB Textiles' ability to marry old and new goes to the heart of their business. They have a vast archive of historic designs that they often draw upon for inspiration. Yet, those designs are now developed with computer assistance. The company has found a way to harness it's 100 year old looms with electronic jacquards allowing the use of CAD.

Margo Graham, one of just two Nottingham lace designers still in existence (her one-time apprentice, Kashka Lennon is the other) explains, "Designing used to be watercolors on draft paper (seen below, left) but now it's computer-aided. The techniques are still the same but all the skills have been transferred. All the cutting and pasting had to be done by hand in the past, now it's a lot easier."

Even with the advent of modern technology, however, there is still much done by hand. Those 100 year old looms are quirky. They run slowly and require careful monitoring.

Once the fabric is loomed, it is taken straight to the darning room to be checked for imperfections. A hand darner will "invisibly" correct any error, be it by adding missed stitches to the pattern or by removing an extra stitch, known as seeding. Not surprisingly, it takes many years to become a good hand darner.

So what's the difference between madras and lace? With madras, below left, the pattern is woven onto a gauze background, so that only the pattern, not the ground, needs to be designed. Lace (below right), on the other hand, requires that both the background and the pattern be designed.

Modern technology or not, its obvious that the lace and madras produced MYB Textiles are imbued with romance from the outset.

EDITOR CREDIT // This post was developed and written by guest editor Lynn Byrne.

IMAGE CREDITS // All lace shown is produced by Morton, Young and Borland Textiles. Quote from Margo Graham taken from an article published in Homes and Antiques magazine in November 2014. Fashion designed by Elizabeth Martin and fashion photos came from Textiles Scotland. All other images from the MYB Textiles website.